UV DTF Printer

UV DTF Printer

Model: GD-302UV

HEAD: F1080

Media Width: ≤ 300mm

Ink: UV Ink

Color: CMYK+W+Varnish

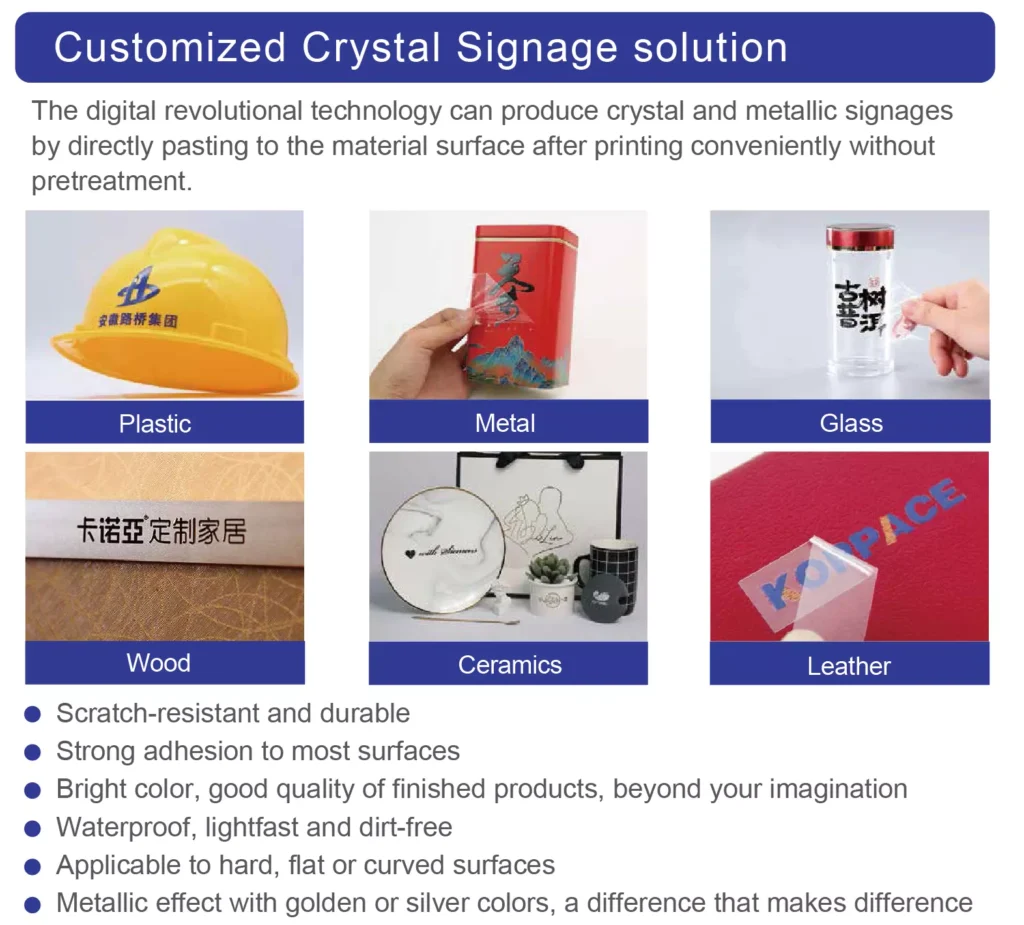

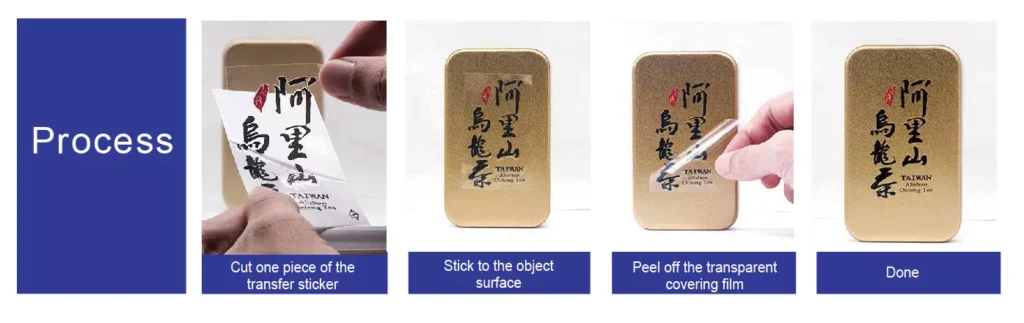

UV DTF printers use UV-curable inks to print vibrant designs, white ink, and varnish onto PET film, creating instant-cure stickers for hard surfaces like metal, glass, wood, and some textiles.

They differ from traditional DTF by curing with UV light instead of powder and heat, offering faster production and better adhesion on non-porous materials.

Key Features

These machines typically feature Epson printheads (like i3200 or i1600), resolutions up to 1440×2880 DPI, and speeds of 5-10 m2/hour depending on passes. They support CMYK+White+Varnish inks, print widths from 30-60cm, and integrated UV LED curing for 3D effects. Power needs are around 1500W at 220V, with sizes fitting small workshops (e.g., 188x95x159 cm, 300kg).

Textile Applications

UV DTF suits textiles via specialized models like UV-60R, offering crack-resistant ink for fabrics with 3D stacking up to 8 layers and dual rigid/soft substrate use. It’s faster than standard DTF (no powdering) but less flexible for stretchy clothes; ideal for faux embroidery or leather.

Maintenance Tips

Clean printheads daily with solution and run cycles to avoid clogs; test ink strips before/after work. Keep away from light to prevent ink drying, maintain dry film, and wipe the machine to block dust. Environment: 15-30 Degree Celsius, 20-70% RH.