Fusing Machine Parts

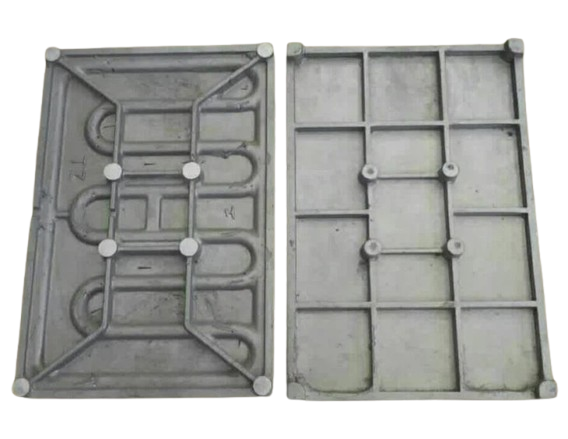

Heating Elements/Trays

Cast aluminium Heating Elements are different shapes of heater which contain heating elements casting in, which have round, flat, square and other shapes which could stick with heating elements after processed.

The surface of board could bear the load reach to 2.5-4.5w/cm2,working temp between 400-500°C.It is have even heating effect,better heat conductance. Our heating elements have long-live time, keep hot better, corrosion resistance and so on. It could be used for heat press machines, clothes or plastic factories, dryers and so on for Heating Element for Heat Press Machine.

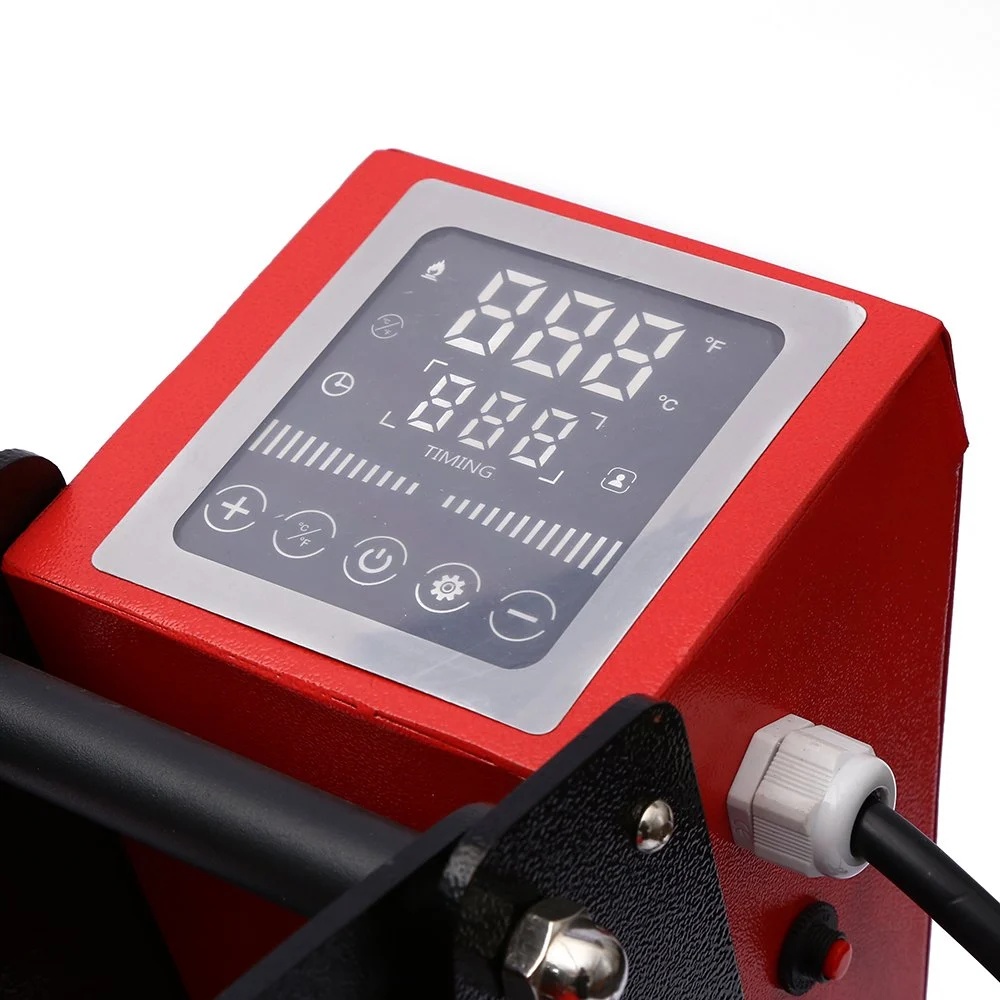

Thermostats

Digital thermostats for textile heating machines provide precise temperature control essential for processes like curing inks, drying fabrics, and heat-setting in digital textile printing. These devices use sensors such as thermistors or RTDs to monitor and maintain set temperatures without mechanical parts, ensuring uniform heating and preventing fabric damage. They often feature programmable settings, LCD displays and compatibility with low-voltage systems common in industrial heaters.

Choose based on voltage, sensor type, and output capacity matching your machine’s wattage (e.g., up to 1000W for smaller units). Look for models with capillary sensors for even distribution in large textile setups. Textsol in India offer certified options compliant with IEC standards.

Control Boxes/Panels

Digital textile heating machine control boxes, also called control panels, manage temperature, timing, and other parameters in textile processing equipment like heat presses, dyeing machines, and yarn heaters. These units ensure precise heating for fabric treatments, sublimation printing, and yarn strengthening. They often feature digital displays, sensors, and automation for efficiency in textile production.

These panels are used in heat press machines for T-shirt printing and sublimation, as well as jet dyeing, yarn dyeing, and TFO machines for yarn softening.

Heater Tubes/Pipes

Digital textile heating machines use specialized heater tubes or pipes to provide precise, uniform heat for processes like curing inks, drying fabrics, or setting dyes in printing and finishing operations. These components ensure efficient energy transfer while maintaining temperature control for high-quality textile output. Common designs include infrared or ceramic tubes for rapid heating.

Heater tubes in these machines typically fall into infrared (IR), quartz, or ceramic categories. IR tubes emit short-or medium-wave radiation for fast, contactless heating up to 800 degree celsius. Quartz pipes offer durability and even heat distribution, often used in conveyor dryers.

Silicone Mats/Wraps

Silicone mats and wraps serve as protective, heat-resistant cushions in digital textile heating machines, ensuring even pressure and heat distribution during printing, curing, and heat transfer processes.

They prevent scorching, ink bleed, and damage to fabrics or machine platens while accommodating irregular surfaces. These components excel in high-volume textile operations like DTG, DTF, and sublimation.