All Printers Parts

Print Heads: Piezo heads, Konica Minolta heads.

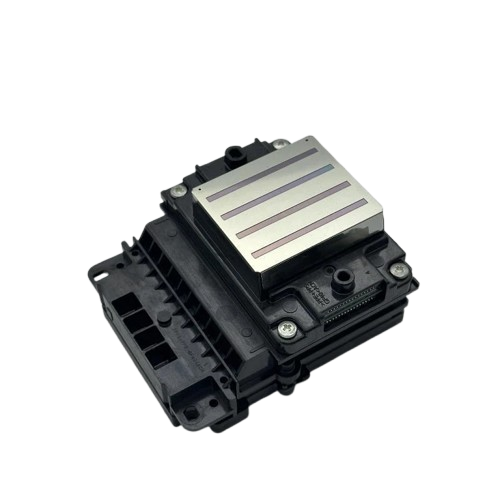

Piezo Head

Piezo heads (piezoelectric printheads) are inkjet printheads that use tiny piezoelectric crystals to mechanically drive ink droplets out of nozzles rather than heat-activate boiling. They are widely used in industrial, textile, packaging, ceramics, and high-quality graphics printing because they can handle many different ink chemistries and offer long service life.

A piezo head contains an ink chamber and a piezoelectric actuator, often made from materials like lead zirconate titanate (PZT).

When voltage is applied, the crystal deforms, creating a pressure pulse that ejects a very precise droplet of ink through the nozzle onto the substrate.

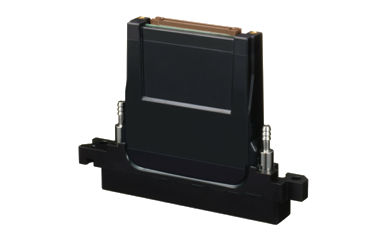

Konica Minolta Head

Konica Minolta produces industrial inkjet printheads, known as “heads”, used in high-speed printing applications like sign graphics, textiles, and electronics. These piezo drop-on-demand heads support various inks, including solvent, UV, and water-based. Key series include KM1024i, KM1800i, and KM512, featuring high nozzle counts and resolutions up to 600 npi.

Mechanical Parts:Motors,belts,print bars,heaters.

Motors

Digital textile printers rely on stepper motors for precise control in fabric handling and print head movement. These motors ensure accurate positioning without drift, vital for high-definition printing on materials like polyester.

Hybrid stepper motors dominate due to high torque and precision, ideal for print head alignment and roller synchronization in weaving or printing processes.

Permanent magnet (PM) steppers suit low-torque tasks like thread feeding, while variable reluctance types handle lighter loads in fabric inspection.

Motors drive warp let-off, take-up mechanisms, and dobby systems to maintain fabric tension and prevent distortion. In digital printing, they manage print heads for high-definition patterns on natural or synthetic fabrics.

Belt

Digital textile printer belts are conveyor systems used in direct-to-fabric printing machines to transport fabrics smoothly during high-speed inkjet printing. These belts handle stretchable and non-stretchable materials like cotton, polyester, silk, and blends without tension, enabling precise designs with reactive, acid, disperse, or pigment inks. They support production speeds up to 1080m2/h in advanced models.

Print Bars

Digital textile printers use printhead bars (one per color) mounted in a carriage or fixed bar to jet ink droplets onto fabric. “Print bars” often refer to these hardware components or visible defects like thin white lines from clogged nozzles during printing.

Printhead bars in digital textile printers consist of multiple nozzles arranged in rows for each ink color, such as cyan, magenta, yellow, and black.

Heaters

Digital textile printer heaters cure inks on fabric after printing by applying controlled heat. These systems fix dyes like reactive, disperse, or pigment inks onto textiles such as polyester, cotton, or blends for vibrant, wash-fast results.