1600MM Heat Transfer Machine

1600 mm Heating Machine

Power – 6.4-12 kW

Max Temperature – 200-250 degree celsius

Voltage – 415-440V, 3 phase

Speed – 20-100 m/h

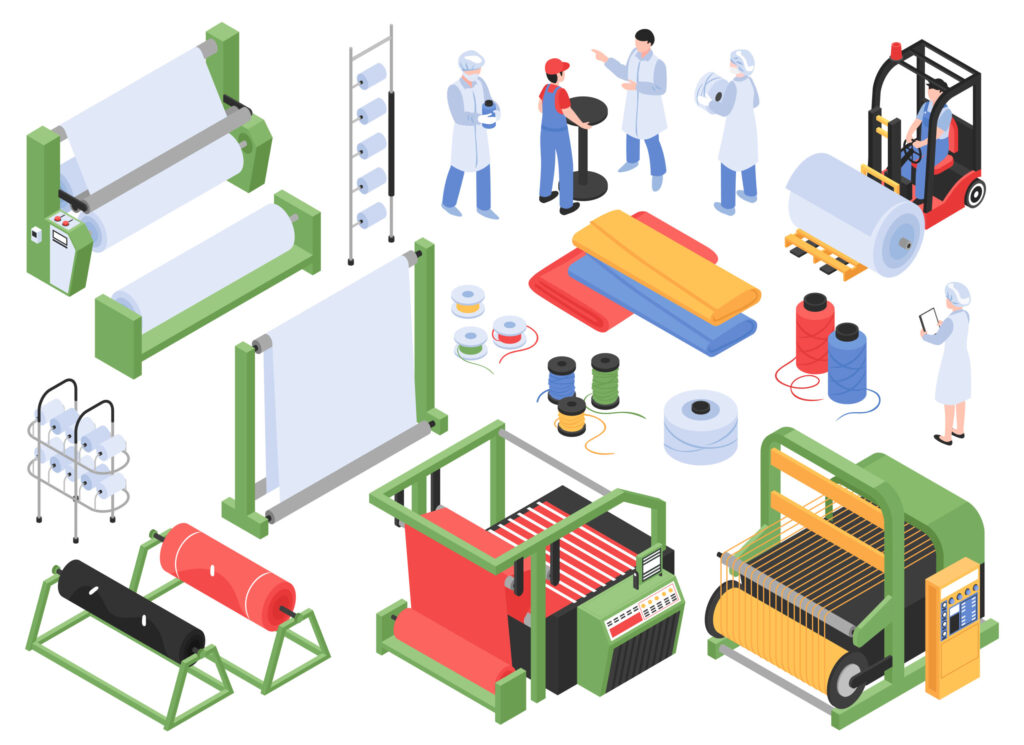

In the digital textile industry, 1600 mm heating machines primarily refer to fusing machines, heat presses, or calendering systems used for processes like DTF, Sublimation, and fabric fixation after printing.

These machines apply controlled heat and pressure to bond inks or transfers onto fabrics, supporting widths up to 1600 mm for efficient production.

They are essential for workflows involving printers, where infrared drying or post-fusing ensures colorfastness.

Key Types

- Fusing Machines: Automatic models for garments and fabrics.

- Sublimation Calenders: Roller heat presses like the Yinghe 1.6m model for continuous cloth transfer printing.

- Pad-Dry or Steaming Units: High-temperature systems (up to 250 degree celsius) for drying and fixation, available in 1600 mm widths.

Average power consumption

1600 mm heat press machines, commonly used in digital textile printing for DTF and sublimation, typically feature rated power between 6-12 kW, but average consumption during operation is lower at 4-8 kW depending on load, temperature, and efficiency.

Power Ratings

Installed power indicates maximum draw during heating, while average reflects steady-state use:

Entry-level models: 12 kW rated, around 6-8 kW average.

Roller Calenders: 6.4-26 kW rated, 17 kW/h average consumption reported for continuous 1600 mm models.

Smaller or pneumatic presses may drop to 1.5-2 kW average, but industrial textile units exceed this for fabric widths.

Factors Affecting Consumption

- Duty Cycle: Peaks at full power (10-36 kW startup), stabilizes 50-70% lower once at temperature (e.g., 200 degree celsius).

- Usage: Continuous production (20-100 m/h) uses more than intermittent; oil-heated drums are efficient at~7 kW for 1600 mm.

- Efficiency Tips: Standby modes, maintenance, and 3-phase 415V setups in India reduce bills; expect 20-50 kWh daily for 8-hour runs.

How heating method affects warm-up time and energy use

Heating methods in 1600 mm heat presses for digital textile printing significantly influence warm-up time and energy use, with oil-heated drums outperforming electric platens or infrared systems in efficiency.

| Parameter | Typical Range/ Specs |

|---|---|

| Working Width | 1600 mm |

| Heating Power | 24-42 kW (e.g., 26 kW for Baba PD 1700D, 42 kW for YL-1600B) |

| Max Temperature | Up to 250-450 degree celsius |

| Speed | 0.2-6 m/min or 20-100 m/h |

| Voltage/Phase | 220V/380V or 415V, 3-phase |

| Weight | ~1700 kg |

| Heating Zones/Plates | 6-12 heaters |

| Material Construction | SS 304/316, MS, Teflon-coated rollers |