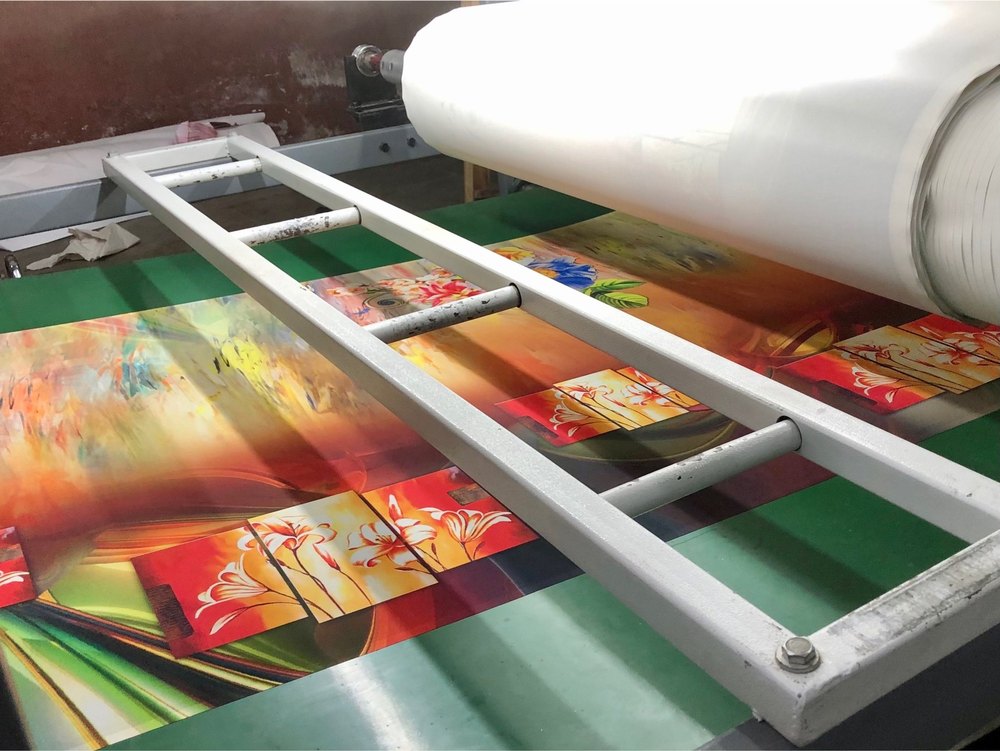

800MM Heat Transfer Machine

800 mm Heating Machine

Capacity – 450-800 mm

Power – 12.5-15 kW

Temperature – 200-400 degree celsius

Printing – DTF or Sublimation

800 mm heating machines typically refer to equipment used in HDPE pipe welding or textile fusing processes, with specifications varying by model and application, such as butt fusion welding. These machines handle pipe diameters from 450-800 mm or fabric widths up to 800 mm, featuring hydraulic systems for clamping and high-temperature heating plates. Common power ratings range from 12-15 kW, suitable for industrial use in construction or printing workflows.

In the digital textile industry, an 800 mm heating machine typically refers to a heat transfer or sublimation machine with an 800 mm diameter drum, used for fixing inks onto fabrics like polyester via roll-to-roll processing.

Key Features

These machines handle widths up to 72 inches (about 1830 mm), operate at temperatures up to 300 degree celsius, and use 3-phase 415V power with 45 kW consumption. Production speeds reach 375-450 meters per hour, ideal for T-shirts, banners, and garments.

These machines feature an 800 mm diameter roller for uniform heating, typically made of Teflon or hard chrome for durability and non-stick performance. They support max temperatures up to 300-399 degree celsius with precise controls for consistent transfers.

Essential safety features for industrial 800 mm heat transfer machine

Industrial heat transfer machines with 800 mm rollers, used in digital textile printing for sublimation and DTF processes, prioritize safety to mitigate risks from high temperatures (up to 300 degree celsius), heavy components (around 3000 kg), and fast production speeds (280-600 m/h).

Core safety features

Emergency stop buttons enable immediate shutdown to prevent accidents during operation. Temperature sensors and overheat protection automatically cut power if limits exceed safe thresholds, avoiding fires or burns. Interlocks halt machine movement if guards are open or safety bars are triggered, protecting operators from pinch points on rollers.

Operator Protections

Safety bars with reverse functionality stop and reverse the roller if contact is detected. Insulated handles, heat-resistant casings, and electro-pneumatic systems reduce electrical and thermal hazards. Protective enclosures around heating elements (often 24 heaters) prevent accidental contact [from prior context].

Maintenance Safeguards

Regular inspection protocols for frayed cables, pneumatic leaks, and pressure calibration minimize electrical shocks and malfunctions. Non-slip surfaces and stable bases prevent tipping on industrial floors.

| Specification | Typical Values |

|---|---|

| Drum Diameter | 800mm |

| Capacity | 400-500m/hour |

| Power Configuration | Three Phase Four Wire 440V |

| Average Power Consumption | 30KW |

| No. of Heater | 30 nos |

| Heating | Oil Heating (160Ltr) |

| Printing Width | 72 in |

| Weight | 3100 kg |

| Machine Size | 2750mm(Length) 1550mm(Width) 2000mm(Height) |

- Production up to 7000 to 21000 meter per day

- 100% Nomex Blanket

- Waste Paper feeding with air shaft and motor

- Seprate and organized Control Panel

- Tension device with gearbox

- 80% Blanket covering area

- Top and Bottom Both Feeding Working

- Light bill reduced up to 10% to 12%

- Pneumatic pressure controlling system